I recently replaced both guibo and CSB and didn't see a DIY so will be assembling this one in stages as I track down the photos and other DIYs. First key part numbers. It appears all E46 cars use the same CSB bearing, but there are three different CSB assemblies. You can buy just the bearing, but I recommend replacing the whole thing unless you somehow know the the bearing is bad but the carrier is okay.

Part I -- Parts

- Guibo 323/325 auto, 330 auto/MT (non-Xi) including ZHP: 26-11-7-511-454

- Guibo 323 or 325 (non-Xi) manual: 26-11-1-227-410

- Guibo 325Xi or 330Xi, manual or auto: 26-11-1-229-360

- Guibo E46 M3: 26-11-2-226-527

- CSB assembly all E46 except Xi/M3: 26-12-7-501-257

- CSB assembly E46 M3: 26-12-2-282-495

- CSB assembly E46 Xi: 26-12-1-229-317

- M12 lock nut for guibo (need 6, single use): 07-12-9-900-047

Optional parts. Replacing the circlip, butyl tape, guibo bolts, intermediate ring, and driveshaft centering sleeve are optional. Some cars don't have the circlip, or intermediate ring. Officially you're supposed to replace all 6 guibo nuts but can re-use the guibo bolts if they're in good shape.

- M12 bolt for guibo, all E46 except M3 6x 26-11-7-523-709

- M12 bolt, M3 3x 26112283795/26117635643 and 3x 26112283795/26117635643

- CSB bearing without support: 26-12-1-225-071

- Circlip, only for 323, 325, 328, and 330xi: 26-12-3-648-156

- Butyl tape for all E46 26-12-7-511-140

- Centering sleeve, driveshaft to transmission: 26117526611

- Intermediate ring (only some models, including ZHP): 26117514120

- Exhaust to manifold flat gasket (x2) part 18107502346 and copper M10 (15mm outside) nuts (x4) part 18301737774

Disclaimer: I only did this on an E46 330i 6-speed. Your E46 may have a different driveshaft setup or require different parts! Double check RealOEM and/or your parts vendor to make sure you gets the right parts.

My starting point was Pelican Parts DIY on replacing the E36 guibo. Also used the Pelican Parts DIY on replacing the CSB. These are pretty good but the ZHP (and probably most or all E46 330s with 6-speed) have a different driveshaft setup.

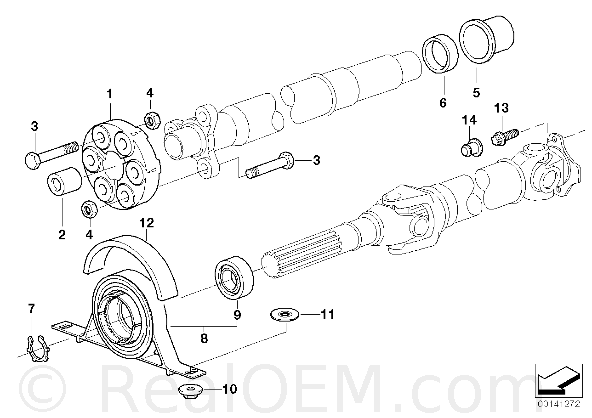

To start, here's what a typical E46 325i driveshaft looks like, from RealOEM. The U-joint is after (behind) the CSB; there is a snap-ring (part #7) keeping the CSB on the rear driveshaft, and locking collar (parts 5 & 6) that holds the two halves together.

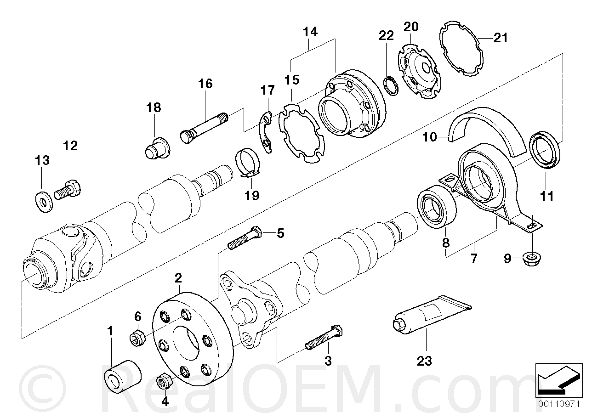

But the ZHP driveshaft is set up more like this, from RealOEM. AFAIK the guibo, CSB, and bolts/nuts for guibo) are the same as the 5-speed, but there is no locking collar or snap-ring. Plus the U-joint is before (in front) of the CSB on my car, even though the diagram shows the U-joint behind the CSB here. A bolt and washer (parts 12 & 13) inside the U-joint holds the two halves together. In this drawing they face forward because U-joint is behind CSB, but in my car they faced backwards because U-joint was in front of CSB--either way the bolt is inside the U-joint and faces toward the CSB.

I was going to post a RealOEM photo of the E46 M3 driveshaft, but it's the same diagram as the ZHP only with some of the part numbers being different.

Reply With Quote

Reply With Quote

I will find this very useful when it comes time for me to replace my GUIBO and centerline bearing. Thanks for getting this all put together!

I will find this very useful when it comes time for me to replace my GUIBO and centerline bearing. Thanks for getting this all put together!